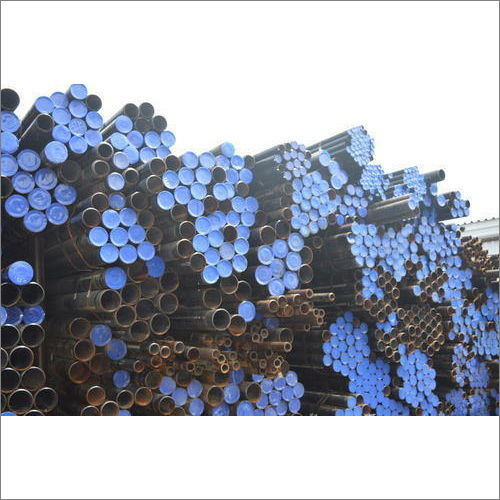

MS Spiral Welded Pipe

Price 90 INR/ Kilograms

MOQ : 100 Kilograms

MS Spiral Welded Pipe Specification

- Feature

- High Strength, Rust Proof, Durable, Leak Proof

- Section Shape

- Circular

- Application

- Oil & Gas, Water Supply, Structural, Construction, Industrial Pipelines

- Tolerance

- 1%

- Connection

- Welded

- End Protector

- Plastic Caps

- Surface Finish

- Galvanized / Painted

- Material

- Mild Steel (MS)

- Product Type

- MS Spiral Welded Pipe

- Thickness

- Diffrent available Millimeter (mm)

- Type

- Welded

- Shape

- Round

- Technique

- Spiral Welded

- Surface Treatment

- Other

- Alloy or Not

- Non-Alloy

- Standard

- ASTM A252, IS 3589, API 5L, IS 1978

- Grade

- Different Available

- Outer Diameter

- 219 mm to 2500 mm

- Size

- Different Available

- Length

- 6 m to 12 m

- Quality

- Tested as per IS/ASTM/API norms

- Weld Type

- Single/Double Side Submerged Arc Welded (SAW)

- Pipe Ends

- Plain/Beveled ends, as required

- Usage

- Suitable for underground and above-ground installation

- Packaging

- Bundled with steel strips or as per requirement

- Pipe Marking

- Standard Marking as per client/order

- Weight

- Customizable as per specification

- Test Certificate

- Available upon request

- Inspection

- Third Party Inspection Available

MS Spiral Welded Pipe Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 7 Days

About MS Spiral Welded Pipe

MS spiral welded pipe is mostly utilized in pipeline systems, water, sludge, dredging, and construction. The manufacture of thin wall pipes with reduced weight per linear foot is one benefit of our offering. In addition to this, the said product finds its application in the transmission of municipal water and wastewater, as well as in the industrial, hydroelectric, and power sectors. MS spiral welded pipe is shaped into the desired diameter of a cylinder using angled rollers. The spiral seam is sealed by an interior and external SAW. It comes in a variety of dimensions.

Versatility for Multiple Applications

MS Spiral Welded Pipes are designed to be adaptable across diverse sectors such as oil & gas transmission, water supply, construction, and industrial pipelines. Their customizable size, grade, and surface finish make them an excellent choice for both underground and above-ground installations. Whether used for structural purposes or in high-pressure pipelines, these pipes deliver consistent performance and reliability.

Enhanced Quality and Compliance

Every MS Spiral Welded Pipe is thoroughly tested as per IS, ASTM, and API norms, with quality assured through rigorous inspections. Third-party verification and test certificates are available upon request for added confidence. Pipes carry standard marking and packaging, ensuring they reach customers in optimal condition, ready for direct use or further fabrication.

Construction with Strength and Durability

Manufactured using advanced spiral welding techniques, these pipes feature high strength, rust-proof durability, and leak-proof joints. End protectors and robust bundling methods protect the pipes during transportation, while precise tolerances (1%) ensure smooth integration into projects. Their reliable performance makes them a preferred solution among distributors, suppliers, and traders across India.

FAQ's of MS Spiral Welded Pipe:

Q: How are MS Spiral Welded Pipes manufactured and what is the welding process used?

A: MS Spiral Welded Pipes are produced using the Spiral Welded technique, which involves forming mild steel strips into a spiral and welding them using Single or Double Side Submerged Arc Welding (SAW). This process ensures robust joints and a leak-proof, high-strength pipe suitable for various demanding applications.Q: What surface finishes and end types are available for these pipes?

A: These pipes are available with either a galvanized or painted surface finish, enhancing protection against corrosion. End types can be supplied as plain or beveled according to client requirements, allowing for seamless installation and integration with existing pipeline systems.Q: When is third-party inspection recommended, and can you provide a test certificate?

A: Third-party inspection is recommended for critical projects that require independent quality verification. We can arrange for third-party inspection upon request and provide comprehensive test certificates to ensure the pipes meet all relevant IS, ASTM, and API standards.Q: Where can these spiral welded pipes be used effectively?

A: These pipes are suitable for both underground and above-ground installations in industries such as oil & gas, water supply, structural construction, and various industrial pipeline networks. Their adaptability makes them ideal for use in demanding and large-scale infrastructure projects.Q: What are the main benefits of choosing MS Spiral Welded Pipes?

A: The primary benefits include high strength, excellent resistance to rust, durable performance, and leak-proof construction. The customizable dimensions and grade, along with strict adherence to global standards, make these pipes a reliable solution for diverse projects.Q: How are the pipes packaged and protected during delivery?

A: Pipes are bundled securely with steel strips or as per specific client requirements. Plastic end caps are used as end protectors to prevent damage during transit, ensuring the pipes arrive in pristine condition for immediate use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MS Pipe Category

Mild Steel Seamless Round Pipe

Price 68 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Seamless

Grade : Industrial

Product Type : Mild Steel Pipes

Surface Treatment : Galvanized

MS Round Seamless Pipes

Price 63 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Seamless

Grade : Industrial

Product Type : Mild Steel Pipes

Surface Treatment : Galvanized

Round MS Pipe

Price 83 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Galvanized

Grade : Industrial

Product Type : Mild Steel Pipes

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS